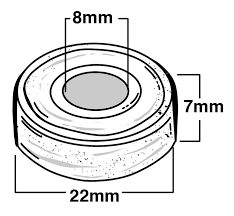

Information about grease buttons

A grease gun, also known as a grease fitting, is a metal assembly used in mechanical systems to feed lubricants, usually greases, into the bearing under medium or high pressure using a grease gun. The grease knob consists of standard knob head grease fittings and metric knob head grease fittings. Grease nipples are designed for high flow of lubricant to provide a smooth working surface for easy connection and removal. Grease buttons can be permanently installed with a threaded or straight push-on ("hammer") arrangement, leaving a pipe connection to which the grease gun connects. The pressure provided by the grease gun forces the small bearing ball in the assembly to move back against the force of the retaining spring. The arrangement is therefore essentially a valve that opens under pressure and allows the lubricant to pass through a channel, thus entering the bearing cavities. When the pressure is released, the bearing returns to its closed position. The bearing ball exclude...